Harvest is Here. Are You Ready For It?

The final applications of Nitrogen are being applied to the corn crop and scouting for insects and plant diseases is in full swing. Capturing and protecting what we can of the crop standing in the field is our highest priority, but what’s next? Planning for harvest is challenging and something that can be overlooked until the last possible moment. In this article, I will list ideas on how you can best prepare your crop and equipment for harvest this fall.

Preparing your equipment

Pre-harvest maintenance tips:

Ensuring your equipment is in working order should be done before harvest season starts, so you’re ready when the crops are. The following steps can either be done yourself or by a local qualified technician.

Inspecting and cleaning

Begin your fall equipment preparation by conducting a thorough inspection. Examine your equipment for signs of wear, damage, or corrosion. Pay close attention to critical components such as pulleys, belts, chains, and filters.

Remove any debris, dust, or residue that might have accumulated during storage. A clean machine operates more efficiently and reduces the risk of contamination, potential fire hazards, and rodent infestation.

Fluid and lubricant checks

Proper fluid levels and lubrication are essential for the equipment’s optimal function. Check the oil levels, coolant, hydraulic fluid, and other relevant fluids according to the manufacturer’s recommendations. Inspect for leaks and ensure they are properly fixed. Proper lubrication of moving parts, such as bearings and joints, will minimize friction, reduce wear and tear, and enhance the overall performance of your machine.

Belt and chain maintenance

Belts and chains play a critical role in the operation of harvest equipment. Inspect them for signs of tension, wear, or misalignment. Tighten or replace belts as needed and ensure that chains are properly lubricated. A well-maintained belt and chain system prevents power loss and enhances the efficiency of your equipment.

Tire and track maintenance

The condition of your equipment’s tires or tracks greatly influences its stability and maneuverability. Inspect the tires for tread wear, cracks, or punctures. For equipment with tracks, ensure they are properly tensioned and aligned. Maintaining the correct tire pressure allows for optimal performance and fuel efficiency.

Electrical system and battery maintenance

Modern harvest equipment relies heavily on electrical systems for various functions. Inspect wiring for any signs of damage or fraying, and make sure connections are secure. Test the battery’s voltage and clean its terminals to prevent corrosion. A reliable electrical system ensures the smooth operation of lights, sensors, controls, and other vital components.

In-season equipment checklist

A thorough pre-harvest equipment review is a necessity, but regular in-season practices can help your equipment stay in peak operating condition. Be sure to incorporate these checklist items into your regular harvest routine:

- Regular Cleaning: Clean equipment after each use to prevent debris buildup.

- Daily Inspections: Conduct daily checks for signs of wear, fluid levels, and tire pressure.

- Greasing and Lubrication: Regularly lubricate moving parts as the manufacturer recommends.

- Belt and Chain Checks: Monitor the condition and tension of belts and chains during operation.

- Fluid Checks: Regularly check oil, coolant, and hydraulic fluid levels, topping off as necessary.

- Tire and Track Maintenance: Inspect tires and tracks for damage and maintain proper tire pressure.

Preparing your Crop

Monitoring your fields for harvest timing is no easy task. Should I harvest all my soybeans and move to corn? Should I switch crops mid-harvest to ensure maximum profit potential? Each of these questions has different answers for different operations. Standability and moisture are the two most important factors to consider when determining when to harvest your crop.

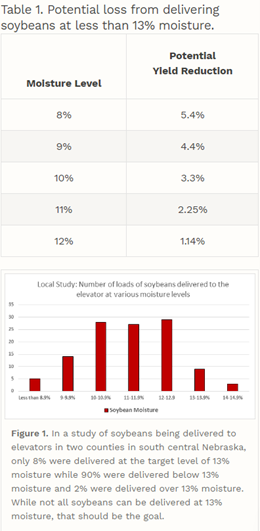

Most soybeans are harvested and delivered directly to an elevator instead of being placed in on- farm storage. Soybeans delivered below or above 13% moisture—the elevator standard—lose potential profit.

At greater than 13% moisture, there is a moisture dock on the scale ticket for delivering wet beans, resulting in a lower price per bushel. And with less than 13% moisture, profit is lost because there are fewer “bushels” to sell rather than a dockage on the ticket (Table 1). There are fewer bushels because the load weight is divided by 60 pounds per bushel (assuming 13% moisture) rather than by the actual pounds per bushel for the moisture content of the beans at the time of delivery.

Walking your fields and scouting for issues, such as lodging, prior to soybean harvest will help you to evaluate which fields to schedule for harvest. Fields with poor standability should be made a priority to ensure harvest loss in decreased.

Scout corn fields to determine harvest priority by assessing stalk quality using either the pinch or push test. The pinch test is done by squeezing the stalk between the second or third internode from the soil surface, if it collapses easily, the stalk may lodge. The push test is done by pushing a stalk to a 45° angle, if it does break or collapse, the stalk may lodge. If 10% or more of the stalks have poor quality or lodge at the root after sampling the field in several areas, the field should be harvested earlier.

Stalk lodging, root lodging, dropped ears, weak and willowing stalks, ear rots are all symptoms you should look for while scouting your corn fields prior to harvest.

What moisture should I harvest my corn? That answer is different for every operation, depending on their drying and storage set up. Ideally you want to harvest your corn with minimum head shatter and low corn moisture. But, the lower the moisture of the corn, usually 15.5%-18%, the higher the head shatter while harvesting.

While you are harvesting both corn and soybeans, make sure you have a notebook along. Taking notes on what hybrids and varieties harvest the easiest and stand the best will be valuable information when you finish harvest and are making decisions on next years purchases. When looking at the yield monitor post-harvest, it’s easy to just look at the yield and forget the characteristics of each product and how it stood in the field. If you forget a notebook, use your cell phone to document with pictures and come back to them later after harvest.

Finally, don’t forget to enjoy your harvest! This is what you work all year for, so take the time to enjoy the fruits of your labor.

Sources

-Plan Harvest to Deliver Soybeans at the Optimum Moisture at https://cropwatch.unl.edu/2017/plan-harvest-deliver-soybean-optimum-moisture