The Corn Test Weight Debate

Test weight and grain quality have been a popular topic of discussion on social media lately. At Hoegemeyer, we take great discussions like this to heart and want to provide information on test weight in corn to use in your next discussion on this topic.

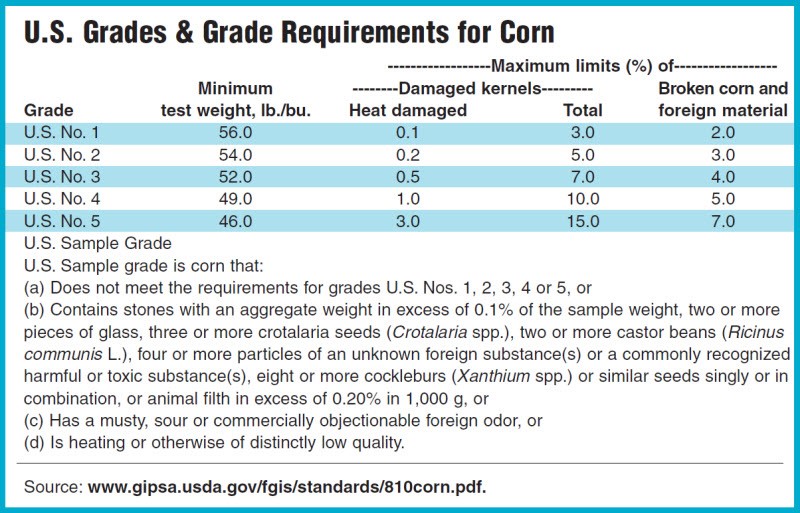

Grain yield and kernel test weight are typical parts of the cafe discussion around hybrid selection in the winter or corn harvest in the fall. Test weight also factors into the price at the elevator when discounts are applied for delivered grain that weighs less than 56 lb/bu. While the terms bushels and test weight are bantered around, it might be worthwhile to dig into these terms and compare their importance at the elevator compared to the feed mill (or total mixed ration mixer).

Low test weight causes

Test weight helps account for the varying densities of grain caused by weather and/or production practices. There are many causes of reduced kernel fill including hybrid genetics, low temperatures, reduced solar radiation (cloudy conditions), premature death due to leaf disease, ear rots, drought and freeze damage to late-developing fields.

When kernels are prevented from filling completely and/or maturing and drying naturally in the field, the starch molecules inside the grain are prevented from the natural process of shedding absorbed water molecules that allows the grain to shrink to a normal size. Artificial drying with heat removes this excess water but the starch molecules do not shrink, and grain size doesn't change appreciably, so test weight remains relatively low.

In some situations, mature kernels significantly hydrated by rain, dew or fog can initiate early germination in the field during which starch is utilized for energy leaving small voids inside the grain. Although the grain may again dry in the field, the seed size does not change, and the small voids inside the seed can result in a decreased test weight.

Test weight for a given hybrid can vary from field to field and from year to year and does not correspond very well to the yield potential of the environment. Data from Purdue University shows the lack of correlation between grain yield and test weight in nitrogen rate trials over multiple site-years in Indiana.

Transportation and storage

At the elevator, 1 bu. of corn is defined as 56 lb. independent of test weight. The weight of the corn for which a seller is paid is, therefore, not affected by test weight - 56 lb. is 56 lb. However, the price the seller receives for a bushel can be affected by test weight. Transporting and storing lower bulk-density grain is more expensive (on a weight basis), so buyers discount grain on a sliding scale if test weight is below minimum standards.

Higher weight per unit volume of grain has obvious advantages in harvest, handling and storage: More bushels will fit in the combine grain tank, on a truck or in a grain bin.

Grain drying

Kernel moisture and test weight are inversely related with higher moisture kernels displaying lower test weight. As corn dries in the field or in a dryer, test weight naturally increases if kernel integrity remains intact. Test weight increases because dried kernels shrink and are slicker so tend to pack more tightly in a quart cup. Kernels are also denser than water, so bulk density goes up as water exits the kernel.

While it is true that test weight will increase due to natural or artificial drying, the increased test weight means the corn will occupy less total volume because of increasing the corn bulk density and could potentially reduce test weight dockage at the elevator. It does not mean there will be any more bushels (pounds) to sell because 1 bu. is 56 lb. regardless of test weight.

When the growing season produces low-test corn, it is important to feed corn based on weight and nutrient content and not volume such as bucket loads.

Livestock considerations

Research on feeding light-test weight corn to dairy cattle is lacking. However, there is a considerable body of research from beef cattle showing that moderately low-test corn (46-48 lb/bu.) results in similar daily gain and feed efficiency to normal corn. This supports an early study from Minnesota showing very little difference in the gross energy of corn ranging from 35 lb to 56 lb/bu.

Due to a lowered starch dilution effect, light-test corn will be higher in crude protein and fiber, so analyzing nutrient content and using modern summative net energy equations may be the best way to determine feeding rates.

Research supports the sage advice of selling high-test weight corn and feeding low-test corn. While test weight, a measure of grain bulk density, has important implications for pricing at the elevator and transportation/storage costs, it has less significance for feeding the grain to ruminants.

The primary watch-outs for feeding light-test corn include a tendency for faster ruminal starch digestion rates, monitoring for mycotoxin levels, the need to feed by weight not volume and close attention to processing consistency.